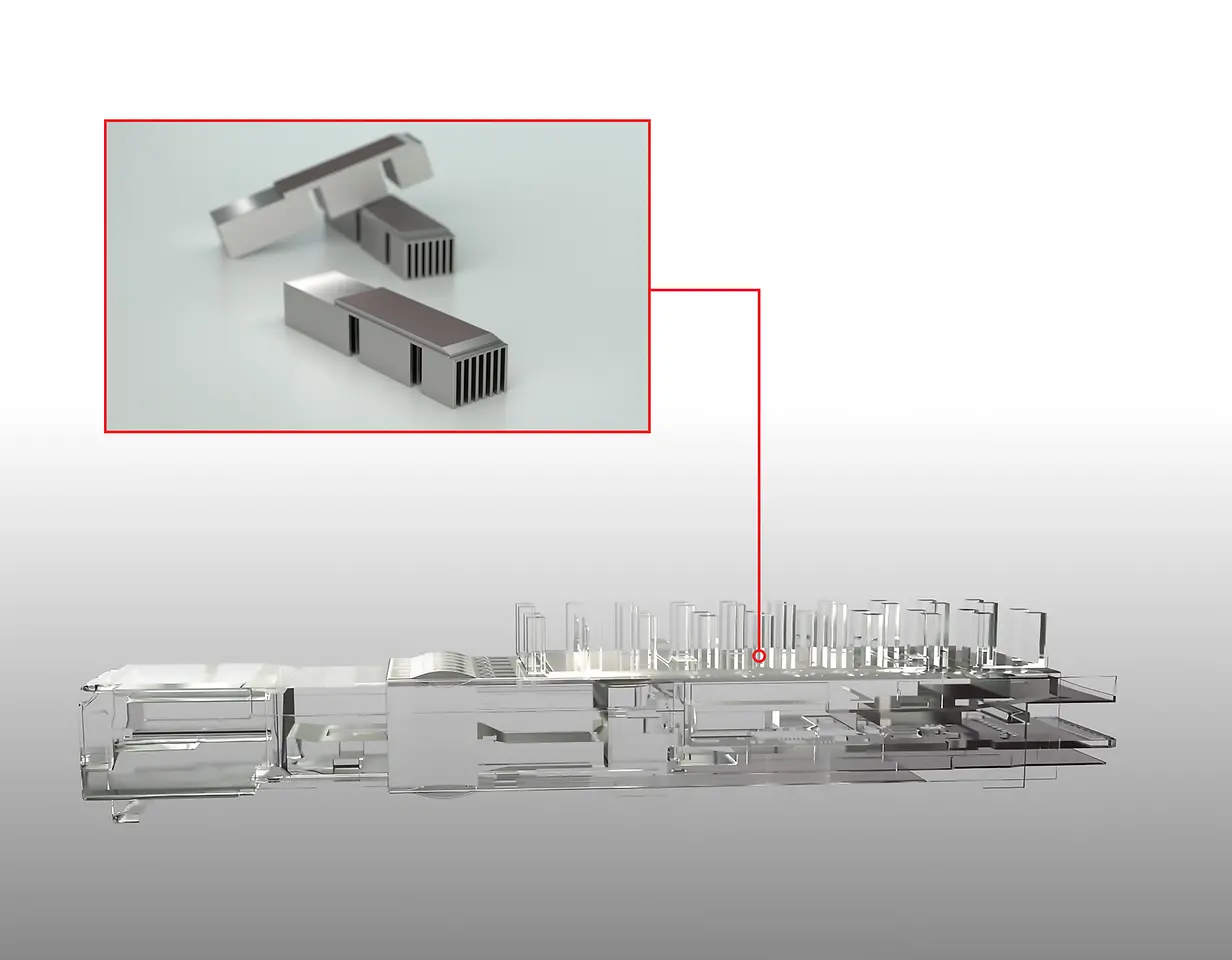

High-capacity POMs can produce as much as 30 watts of power in operation, generating performance-diminishing heat. Current approaches to thermal control involve conventional metal-to-metal interfaces (transceiver to riding heat sink) and the use of adhesive-applied phase change materials. Henkel’s coating materials offer a more robust solution with the company’s most recent formulation, Bergquist microTIM mTIM 1028, designed to deliver enduring thermal control for high bandwidth density POMs. These devices are typically constructed with nickel housings and interface with nickel-coated copper heatsinks for system heat removal. Compared to alternatives, Bergquist microTIM mTIM 1028 can withstand as many as 500 pulls and insertions without performance degradation and reduces operational temperatures per POM by as much as 0.18° C/W.

“With today’s data throughput expectations, heat control is one of the most effective ways to improve operational efficiency,” explains Wayne Eng, Global Head of Data & Telecom Market Strategy at Henkel. “Our groundbreaking microTIM is well-proven with standard aluminum-based riding heatsinks and is now extended to nickel-coated copper heatsinks often employed with higher-bandwidth modules. Furthermore, the material can also be coated on the transceiver, providing a value-added solution for POM manufacturers as a point of competitive differentiation.”

Internal testing of Bergquist microTIM mTIM 1028 with a QSFP-DD 400 Gb module revealed the following:

“Our approach to heat control in hyperscale data center line cards is a critical development for future performance objectives,” says Eng. “While conventional thermal management methods are adequate for 100 Gb POMs, the bandwidth and reliability demands of next-generation links are tremendous. We believe this new material innovation is an important element for line card thermal control and performance optimization, and could potentially play a role in reducing heat within other data center applications, such as liquid cooling pipes and plates.”

Henkel’s nickel-compatible Bergquist microTIM mTIM 1028 is the latest material in the company’s microTIM line and is available for sampling on request. For more information about Henkel’s data center solutions, visit this resource.